Crude oil tank cleaning Equipment

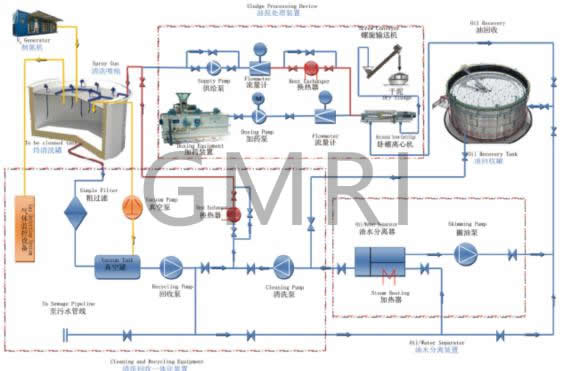

1、Crude oil tank cleaning equipment working principal introduction

1.1 Working Principal

At first, using the temporary pipes connect the 150,000m3 crude oil tank or smaller and the equipments to be a closed loop cleaning system . after that, use the same oil as the tank storage to broke the oil sludge. when the sludge is broken, to become liquid and small, it will be pumped out, and be separated、recycled, when most sludge and oil is pumped out, than, using hot water to clean the tank, at last, the tank will be cleaned up. This closed process is called crude oil tank cleaning technology.

1.2 technological process

Bottom oil transfer→ inject Nitrogen→ oil cleaning→hot water cleaning→open manhole/ventilate→clear up

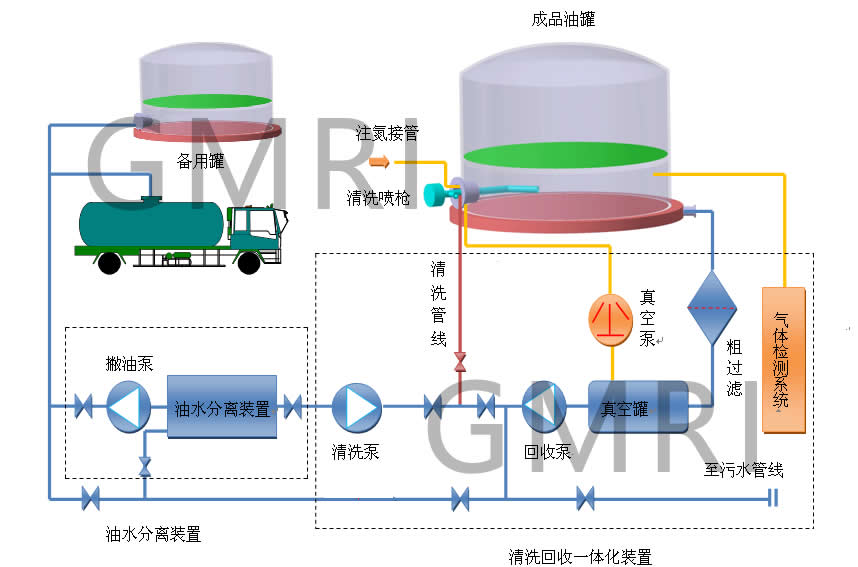

2、Product oil storage tank cleaning system working principal introduction

2.1 working principal

At first, using the temporary pipes connect the 50,000m3 refined oil tank or smaller and the equipments to be a closed loop cleaning system . after that, using hot water to clean the tank, the oil /water will be pumped out, and be separated、recycled , at last, the tank will be cleaned up. This closed process is called refined oil tank cleaning technology.

2.2 technological Process

Equipment installation→inject Nitrogen→hot water cleaning→open manhole/ventilate→clear up

3、Equipment introduction

The GM tank cleaning system is used for cleaning the 1,000 m3-150,000 m3 crude oil tank and product oil tank.

3.1 Equipment composition

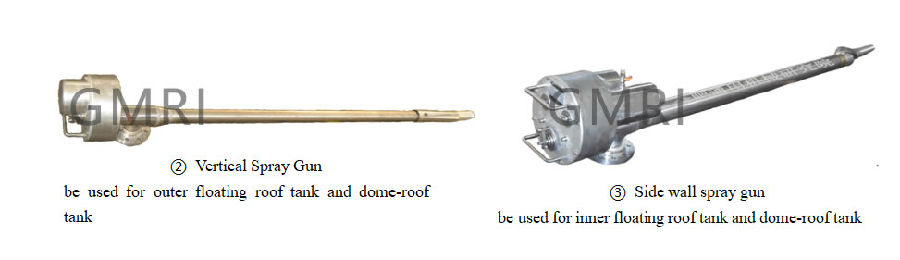

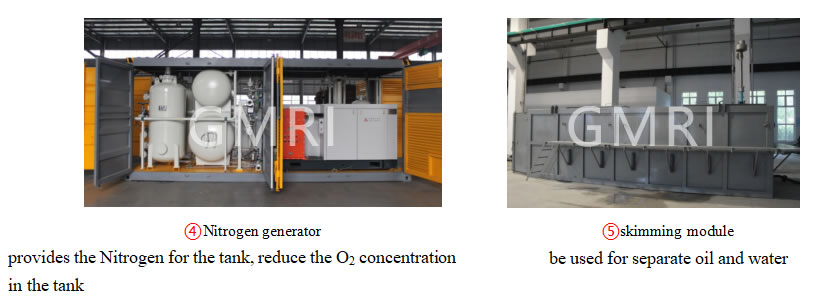

① Cleaning /recycling module ② Vertical Spray Guns ③ Side wall spray guns ④ Nitrogen generator ⑤ skimming module ⑥ Tube & Pipe Assy

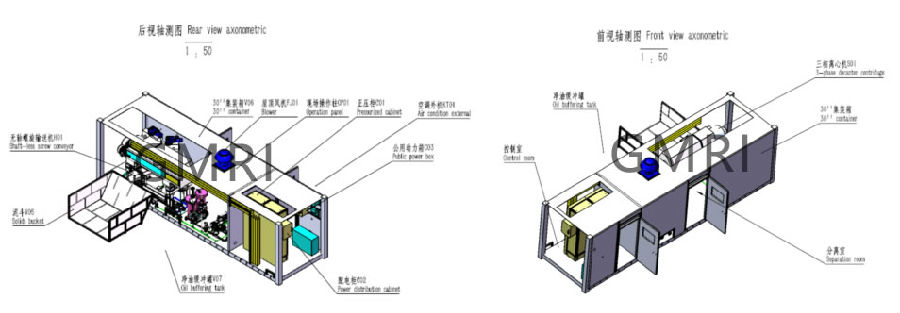

① Cleaning /recycling module

The cleaning /recycling module include recovery pump unit、ejecting pump unit、vacuum pump unit and O2 monitor. All of these units integrate in a open type container.

⑥Tube & Pipe Assy: diaphragm pump、switch box、cable、air compressor、filter、pipes、valves, and so on.

3.2 Technical specifications

No | name | type | GM-L | GM-M | GM-S |

Rang of application | 150,000 m3and smaller crude oil tank | 50,000 m3and smaller crude/product oil tank | 30,000 m3and smaller crude/product oil tank |

1 | Cleaning /recycling module | flow | 180m3/h | 120m3/h | 80m3/h |

vacuum draw | 230m3/h | 165m3/h |

detection object | O2、 flammable gas |

detecting point | 6 points | 4-6 points |

power | 155 kW | 115kW | 95kW |

dimension | 7m×2.3m×2.7m | 6.5m×2.3m×2.5m | 6.5m×2.3m×2.5m |

2 | Vertical Spray Gun | flow | 40m3/h~80m3/h(ADJ) |

pressure | 0.5MPa~0.7MPa |

3 | Side wall spray gun | flow | / | 40m3/h~90m3/h(ADJ) |

pressure | / | 0.5MPa~0.7MPa |

4 | Nitrogen generator | generation rate | 300m3/h | 200m3/h |

purity | 99%VOL |

5 | Skimming module | dimension | 7m×2.3m×2.6m | 6m×2.3m×2.6m |

volume | 20m3 | 15m3 |

6 | Diaphragm pump | / | flow:24m3/h, pressure:0.6MPa |

7 | Switch box | / | 400A,EXDIIBT4,IP55, leakage protection |

8 | Cable | / | Three phase/anti-flaming/wear resistant |

9 | Air compressor | / | EXDIIBT4,IP55 |

10 | Filter | / | Double type DN 600,bear pressure 1.6MPa,quick-open type |

11 | Pipe | / | bear pressure 1.6MPa, static conductivity |

3.3 Oil and Solid separator

The oil and solid separator consists of pre-treatment system、feed pump、centrifugal machine、chemical dosing system 、screw conveyer、 fuel delivery pump and so on, fit for separating the solid、water and oil .

oil and solid separation effect

4、technical advantage

(1) Safety: Explosion proof design, the nitrogen generator is the safety guarantee.

(2) Efficiency: all mechanical work, 24 hours continue working, no person entry the tank in cleaning process.

(3) Environmental friendliness: fully closed pipelining operations, no oil leakage, no pollution.

(4) Efficiency: oil/water separator make the water can be recycled.

(5) Professional: more than 200 spray guns be used in cleaning tank, our oil tank cleaning system have cleaned more than 200 tanks for petroleum/Sinopec/National oil storage base in China and southeast Asia customer .

(6) Technological Achievements: the oil tank cleaning system has our own many invention patents, won “China machinery industry science and technology first prize” , and set a machinery industry standard JB/T 13138-2017.

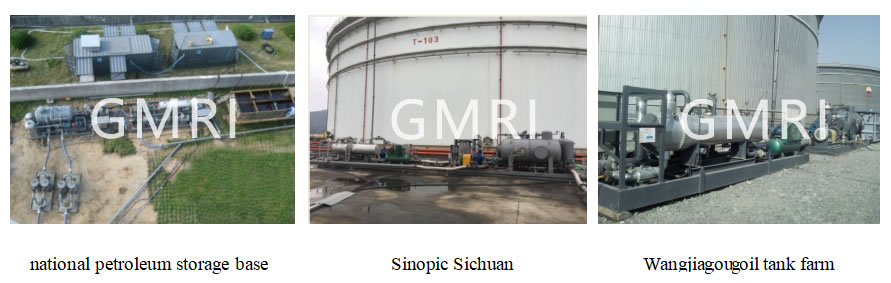

5、Engineering Projects

The GM large oil storage tank cleaning equipments have been used to clean many big tanks in Xinjiang province/Gansu province/Zhejiang province/Sichuan province/Xian province/Beijing/Tianjin and in Southeast Asia, the good cleaning effect get the customer’s high praise.